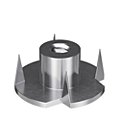

Threaded Inserts

Threaded inserts repair stripped threads or create new permanent threads in a mounting surface. They can convert a threaded hole between standard and metric fasteners. Helical inserts, self-locking inserts, and key-locking inserts install into threaded holes and repair their threads or change their diameter. Rivet nuts and nut inserts install through the mounting surface and grip it from both sides, creating a female-threaded mounting point. Self-tapping inserts create their mounting threads as they are screwed into place. Press-fit inserts compress to fit into their installation hole and expand to lock in place when the male fastener is screwed in. Heat-set inserts install into the mounting surface by melting it using an installation tool or soldering iron. Weld nuts are welded to metal surfaces and provide a female-threaded mounting point. T-nuts for wood embed into wood mounting surfaces and create a female-threaded hole. Socket nuts can function as both Allen nuts and inserts.